Product Description

Product Description

| Plum Pad: Plum CHINAMFG mat, full name plum-shaped elastic coupling cushion. It is used for cushioning of various heavy machinery coupling shafts. Some areas are also known as plum CHINAMFG plates. According to the material, it can be divided into polyurethane plum mat and rubber plum mat, nylon plum mat. |

| Plum Pad Classification: Plum CHINAMFG mat is divided into MT type plum CHINAMFG mat, T-shaped hexagonal mat, GR star plum CHINAMFG mat, HRC hexagonal mat, NM type elastic ring, L-shaped hexagonal pad, NL nylon inner tooth sleeve, H-type elastic block, rubber gear, etc. |

| Plum Pad Characteristics The plum CHINAMFG pad is used for damping, insulation and buffer transmission torque in the middle of the coupling. The torque transmitted by the plum CHINAMFG pads of different materials and different hardness is also different. The higher the hardness, the greater the torque transmitted. |

Detailed Photos

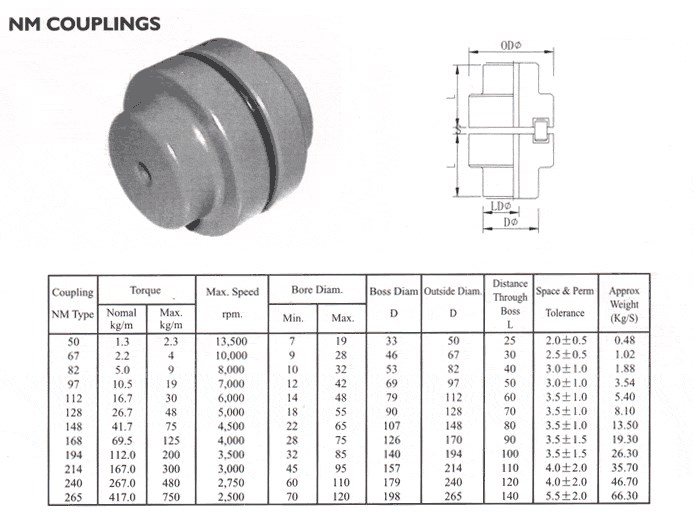

Size List

Other Seals

Company Profile

Our company was founded in March 2005 and is located in HangZhou, a world-famous coastal city. We cover a total area of 20,000 square meters, including 8,000 square CHINAMFG of construction area. We have more than 110 employees, including 35 technicians and 3 senior engineers. Our company is 1 of the top 100 excellent auto parts suppliers in China. We are professional enterprise specializing in the production of seals. And we were separated from the former state-owned HangZhou Seals Factory. We have strong technical capabilities and 30 years of seal

manufacturing technology and experience. Specializing in the production of rubber products such as skeleton oil seals, sealing rings, O-rings, and rubber parts. We provide supporting services for many CHINAMFG domestic brands of engines, machinery, hydraulic press, etc.

We have the world’s most advanced automatic production lines and testing equipments, such as digital projectors, electronic tensile testing machines, computerized rotorless curemeters , high-precision life test benches, etc. The annual production capacity reaches 200 million pieces. We have also passed ISO9001:2000 quality management system, ISO9001:2008 quality management system and TS16949 international certification. Products are sold to all provinces and regions of China, and exported to the united Arab emirates, Russia, Japan, Europe, the United States and other countries.

We will continue to work hard in production, quality control, technology, research and development, management and service to achieve our business goal – – – becoming a world-class sealing enterprise.

Our Advantages

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material 1: | TPU PU Nr PA NBR Silicone EPDM |

|---|---|

| Material 2: | Polyurethane Rubber |

| Colour: | Red Black Yellow Blue Milk Green |

| Structure: | Gr GS Mt HRC Nm Nl T L Tgl TXT Txd |

| Use for: | High Transmission Flange |

| Name 1: | Spiders Coupling |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Are there any safety considerations when using flexible couplings in rotating machinery?

Yes, there are several safety considerations to keep in mind when using flexible couplings in rotating machinery. While flexible couplings offer numerous benefits in terms of misalignment compensation, vibration isolation, and shock absorption, improper use or maintenance can lead to safety hazards. Here are some important safety considerations:

- Proper Installation: Ensure that the flexible coupling is installed correctly and securely following the manufacturer’s guidelines. Improper installation can lead to coupling failure, unexpected disconnection, or ejection of coupling components, which may result in equipment damage or injury to personnel.

- Alignment: Proper shaft alignment is essential for the reliable and safe operation of flexible couplings. Misaligned shafts can cause excessive stress on the coupling and connected components, leading to premature wear and possible failure. Regularly check and maintain proper shaft alignment to prevent safety risks.

- Operating Conditions: Consider the environmental and operating conditions of the machinery when selecting a flexible coupling. Some couplings are designed for specific temperature ranges, hazardous environments, or corrosive atmospheres. Using a coupling that is not suitable for the operating conditions can compromise safety and performance.

- Torque and Speed Limits: Always operate the flexible coupling within its specified torque and speed limits. Exceeding these limits can cause coupling failure, leading to unexpected downtime, equipment damage, and potential safety hazards.

- Maintenance: Regularly inspect and maintain the flexible coupling to ensure its continued safe operation. Check for signs of wear, damage, or corrosion, and promptly replace any worn or damaged components with genuine parts from the manufacturer.

- Emergency Stop Mechanism: In applications where safety is critical, consider implementing an emergency stop mechanism to quickly halt machinery operation in case of coupling failure or other emergencies.

- Personal Protective Equipment (PPE): When working with rotating machinery or during maintenance tasks involving couplings, personnel should wear appropriate PPE, such as gloves, eye protection, and clothing that can resist entanglement hazards.

- Training and Awareness: Ensure that personnel working with the machinery understand the potential hazards associated with flexible couplings and receive proper training on safe handling, installation, and maintenance procedures.

By adhering to these safety considerations, operators and maintenance personnel can mitigate potential risks and ensure the safe and reliable operation of rotating machinery with flexible couplings. Additionally, it is essential to comply with relevant safety standards and regulations specific to the industry and application to ensure a safe working environment.

How does a flexible coupling impact the overall reliability of connected equipment?

A flexible coupling significantly impacts the overall reliability of connected equipment in several ways:

- Misalignment Compensation: Flexible couplings can accommodate both angular and parallel misalignment between connected shafts. By allowing for misalignment, the coupling reduces the stress and wear on bearings, seals, and other rotating components. This feature prevents premature failure of these components, contributing to improved reliability and extended equipment lifespan.

- Vibration Damping: Flexible couplings possess inherent damping properties due to their elastomeric or flexible elements. These elements absorb and dissipate vibrations generated during the operation of machinery. By dampening vibrations, the coupling protects the connected equipment from excessive oscillations, reducing fatigue and preventing mechanical failures. This enhanced vibration control increases the reliability of the system.

- Shock Load Absorption: In applications with sudden load variations or shock loads, such as in heavy machinery or high-speed equipment, a flexible coupling acts as a shock absorber. It can absorb and dissipate the impact energy, protecting the machinery from damage caused by sudden loads. The ability to absorb shock loads contributes to the overall reliability of the connected equipment.

- Reduced Wear and Tear: The flexibility of the coupling minimizes stress and wear on rotating equipment. It allows for slight movements and misalignments, reducing friction and stress on bearings and other critical components. This reduction in wear and tear lowers the frequency of maintenance and replacement, increasing the overall reliability of the equipment.

- Compensation for Thermal Expansion: Temperature changes in machinery can lead to thermal expansion or contraction of shafts. A flexible coupling can compensate for these thermal effects, ensuring that the machinery remains properly aligned even as temperature conditions fluctuate. This compensation prevents binding and misalignment, promoting reliable performance.

- Protection Against Overloads: Flexible couplings help protect connected equipment from overloads and torsional vibrations. They act as a mechanical fuse, disconnecting the driveline when an overload occurs, thus preventing damage to expensive machinery. This safety feature enhances the overall reliability and reduces the risk of catastrophic failures.

- Easy Maintenance and Alignment: Flexible couplings are designed for easy installation and alignment. This feature simplifies maintenance procedures, making it easier to inspect and replace couplings when necessary. Properly aligned couplings lead to improved equipment performance and longevity, enhancing overall reliability.

By compensating for misalignment, damping vibrations, absorbing shock loads, reducing wear and tear, and providing other protective features, a flexible coupling significantly improves the reliability of connected equipment. It extends the lifespan of critical components, minimizes downtime, and ensures smooth and efficient operation, making it a valuable component in various industrial applications.

How do you select the appropriate flexible coupling for a specific application?

Choosing the right flexible coupling for a specific application requires careful consideration of various factors to ensure optimal performance, reliability, and longevity. Here are the key steps to select the appropriate flexible coupling:

- Application Requirements: Understand the specific requirements of the application, including torque and speed specifications, misalignment conditions, operating environment (e.g., temperature, humidity, and presence of corrosive substances), and space limitations.

- Torque Capacity: Determine the maximum torque that the coupling needs to transmit. Choose a flexible coupling with a torque rating that exceeds the application’s requirements to ensure a safety margin and prevent premature failure.

- Misalignment Compensation: Consider the type and magnitude of misalignment that the coupling needs to accommodate. Different coupling designs offer varying degrees of misalignment compensation. Select a coupling that can handle the expected misalignment in the system.

- Vibration Damping: If the application involves significant vibrations, choose a flexible coupling with good damping properties to reduce vibration transmission to connected equipment and improve system stability.

- Environmental Factors: Take into account the environmental conditions in which the coupling will operate. For harsh environments, consider couplings made from corrosion-resistant materials.

- Torsional Stiffness: Depending on the application’s requirements, decide on the desired torsional stiffness of the coupling. Some applications may require high torsional stiffness for precise motion control, while others may benefit from a more flexible coupling for shock absorption.

- Cost and Life-Cycle Considerations: Evaluate the overall cost-effectiveness of the coupling over its expected life cycle. Consider factors such as initial cost, maintenance requirements, and potential downtime costs associated with coupling replacement.

- Manufacturer Recommendations: Consult coupling manufacturers and their technical specifications to ensure the selected coupling is suitable for the intended application.

- Installation and Maintenance: Ensure that the selected flexible coupling is compatible with the equipment and shaft sizes. Follow the manufacturer’s installation guidelines and recommended maintenance practices to maximize the coupling’s performance and longevity.

By following these steps and carefully evaluating the application’s requirements, you can select the most appropriate flexible coupling for your specific needs. The right coupling choice will lead to improved system performance, reduced wear on equipment, and enhanced overall reliability in various mechanical systems and rotating machinery.

editor by CX 2024-03-03