-

Star flexible coupling

-

Plum-shaped elastic coupling

-

Slider coupling

-

Diaphragm coupling

-

Elastic sleeve pin coupling

-

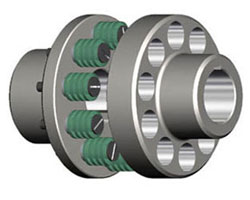

Elastic pin coupling

-

Elastic pin gear coupling

-

Drum gear coupling

-

Rigid coupling

-

Tyre coupling

-

Universal coupling

-

Water pump coupling

-

Roller chain coupling

-

Reducer bracket

-

Blender

-

Stuffing box

-

Expansion sleeve

-

Various coupling accessories

-

Product Navigation

- LM type basic plum blossom elastic coupling

- LT type (formerly TL type) elastic sleeve pin coupling

- LMD (formerly MLZ) type single flange plum-shaped bullet

- XL type star elastic coupling

- Function selection and marking of coupling

- Operation and structure of star coupling

- The editor will introduce you to each model

- The coupling is divided into lubricated and non-lubricated

-

Update

Elastic sleeve pin coupling

- What is steel casting, the advantages of steel castings and heat treatment

Cast steel is an alloy with iron and carbon as the main elements, with a carbon content of 0 to 2%, and is used for pouring castings.Cast steel is divided into cast carbon steel, cast low alloy steel and cast special steel. ...

- What are the characteristics of the slider coupling?

The material of the slider coupling parts can be 45 steel, and the working surface needs to be heat treated to increase its hardness; Q275 steel can also be used when the requirements are low, without heat treatment.In order to reduce friction and wear, oil should be injected from the oil hole of the intermediate plate for lubrication during use. ...

- What are the different functions of single diaphragm coupling and double diaphragm coupling?

The diaphragm of the diaphragm coupling consists of a diaphragm and two shaft sleeves.The diaphragm is fastened to the shaft sleeve with a pin and generally does not loosen or cause backlash between the diaphragm and the shaft sleeve.This characteristic is a bit like a bellows coupling, in fact the way the coupling transmits torque is poor...

- Code mark of coupling hole and keyway form

The hole type code of the coupling is: Y type-long cylindrical shaft hole; Z type-long conical shaft hole with counterbore; J type-short cylindrical shaft hole with counterbore; Z1 type-no counterbore Long conical shaft hole; J1 type-short cylindrical shaft hole without counterbore. ...

- Which elastic pin couplings are more commonly used?

Commonly used pin coupling models are: elastic sleeve pin coupling (TL), elastic pin coupling (HL), elastic pin gear coupling (LZ).There are HL1 to HL14 models of elastic pin couplings.The elastic pin coupling has a simple structure...

- What is the nominal torque of the coupling and how is it calculated?

The nominal torque of the coupling is plain, that is, what is the force on the shaft?Then multiply it by the radius of the shaft, which is called torque. The nominal torque of the coupling is the limit value to ensure that the coupling does not cause fatigue damage when the shaft is twisted. ...

- LT type (formerly TL type) elastic sleeve pin coupling

LT type (formerly TL type) elastic sleeve pin coupling (GB4323-2002 instead of GB4323-1984) elastic sleeve pin coupling uses a pin with an elastic sleeve (rubber material) at one end and is installed in the two halves. In the flange hole of the shaft to realize the connection of the two halves of the coupling...

- How to choose the diaphragm coupling correctly?

The diaphragm coupling consists of at least one diaphragm and two sleeves. The diaphragm is fastened to the sleeve with a pin and generally will not loosen or cause backlash between the diaphragm and the sleeve...

- The structural characteristics of the safety coupling

The structural feature of the safety coupling is that there is a safety link (such as a movable pin connection, etc.), which can only withstand a limited load. When the actual load exceeds the previously limited load, the safety link changes, cutting off the movement and Transmission of power...

- How to choose gear coupling?

When the gear coupling is working, the two shafts produce relative angular displacement. The tooth surfaces of the internal and external teeth periodically slide relative to each other in the axial direction, which will inevitably cause tooth surface wear and power consumption. Therefore, the gear coupling needs to have a good and Working in a sealed state....