-

Star flexible coupling

-

Plum-shaped elastic coupling

-

Slider coupling

-

Diaphragm coupling

-

Elastic sleeve pin coupling

-

Elastic pin coupling

-

Elastic pin gear coupling

-

Drum gear coupling

-

Rigid coupling

-

Tyre coupling

-

Universal coupling

-

Water pump coupling

-

Roller chain coupling

-

Reducer bracket

-

Blender

-

Stuffing box

-

Expansion sleeve

-

Various coupling accessories

-

Product Navigation

- LM type basic plum blossom

- LT type elastic sleeve pincoupling

- LMD type single plum-shaped

- XL type star elastic coupling

- Couplings change with the needs

- It's Mid-Autumn Festival again

- Hangzhou Hengli Factory Slider

- Hengli explains elastic pin teeth

- Operation and structure of

- The editor will introduce you to

- The coupling is divided into

- What to consider when buying a

-

Update

-

Product display Coupling > Product > Plum-shaped elastic coupling >

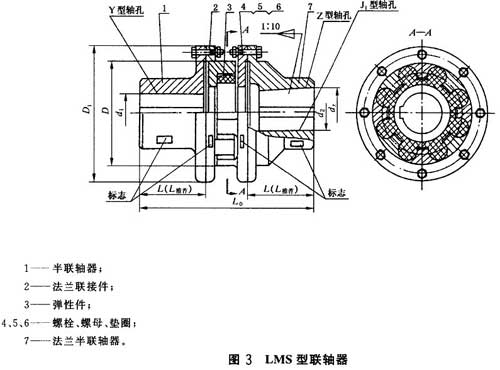

LMS (formerly MLS) type double flange plum blossom elastic coupling

时间:2013-08-01 17:50 作者:admin 点击:

次

Detailed parameters of LMS (formerly MLS) type double flange plum blossom elastic coupling

The scope of application and performance characteristics of LMS (formerly MLS) type-double flange plum blossom elastic coupling

1. LMS (formerly MLS) type-double flange type plum blossom elastic coupling is mainly composed of two protruding teeth that are closely meshed and subjected to radial compression to transmit torque. When the two axes are relatively offset, the elastic element occurs The corresponding elastic deformation plays a role of automatic compensation.

2.梅花形弹性联轴器主要适用于起动频繁、正反转、中高速、中等扭矩和要求高可靠性的工作场合,例如:冶金、矿山、石油、化工、起重、运输、轻工、纺织、 水泵、风机等。工作环境温度 -35℃~+80℃,传递公称扭矩25~12500Nm,许用转速1500~15300r/min。

The material of the elastic element of the plum blossom elastic coupling is

Basic parameters and main dimensions of LMS (formerly MLS) type double flange plum blossom elastic coupling (GB/T 5272-2002) (Unit: mm)

| model | Old model | Nominal torque/Nm | Allowable speed/r/min | Diameter of shaft hole d1,d2,dz | Length of shaft hole | L | Lo | D | Dl | Elastic part model | Weight/kg | Moment of inertia/kg.㎡ | ||

| Elastic part hardness | Y type | J1, J, Z type | ||||||||||||

| a/Ha | b/Hb | L | L1 | |||||||||||

| 80±5 | 60±5 | |||||||||||||

| LMS1 | MLS1 | 25 | 45 | 8500 | 12,14 | 32 | 27 | 35 | 98 | 50 | 90 | MT1 | 1.33 | 0.0013 |

| 16,18,19 | 42 | 30 | ||||||||||||

| 20,22,24 | 52 | 38 | ||||||||||||

| 25 | 62 | 44 | ||||||||||||

| LMS2 | 无 | 50 | 100 | 7600 | 16,18,19 | 42 | 30 | 38 | 108 | 60 | 100 | MT2 | 1.74 | 0.0021 |

| 20,22,24 | 52 | 38 | ||||||||||||

| 25,28 | 62 | 44 | ||||||||||||

| 30 | 82 | 60 | ||||||||||||

| LMS3 | MLS2 | 100 | 200 | 6900 | 20,22,24 | 52 | 38 | 40 | 117 | 70 | 110 | MT3 | 2.33 | 0.0034 |

| 25,28 | 62 | 44 | ||||||||||||

| 30,32 | 82 | 60 | ||||||||||||

| LMS4 | MLS3 | 140 | 280 | 6200 | 22,24 | 52 | 38 | 45 | 130 | 85 | 125 | MT4 | 3.38 | 0.0064 |

| 25,28 | 62 | 44 | ||||||||||||

| 30,32,35,38 | 82 | 60 | ||||||||||||

| 40 | 112 | 84 | ||||||||||||

| LMS5 | MLS4 | 350 | 400 | 5000 | 25,28 | 62 | 44 | 50 | 150 | 105 | 150 | MT5 | 6.07 | 0.0175 |

| 30,32,35,38 | 82 | 60 | ||||||||||||

| 40,42,45 | 112 | 84 | ||||||||||||

| LMS6 | MLS5 | 400 | 710 | 4100 | 30,32,35,38 | 82 | 60 | 55 | 167 | 125 | 185 | MT6 | 10.47 | 0.0444 |

| 40,42,45,48 | 112 | 84 | ||||||||||||

| LMS7 | MLS6 | 630 | 1120 | 3700 | * 35, 38 * | 82 | 60 | 60 | 185 | 145 | 205 | MT7 | 14.22 | 0.0739 |

| 40*,42*,45,48,50,55 | 112 | 84 | ||||||||||||

| LMS8 | MLS7 | 1120 | 2240 | 3100 | 45*,48*,50,55,56 | 70 | 209 | 170 | 240 | MT8 | 21.16 | 0.1493 | ||

| 60,63,65 | 142 | 107 | ||||||||||||

| LMS9 | MLS8 | 1800 | 3550 | 2800 | 50*,55*,56* | 112 | 84 | 80 | 240 | 200 | 270 | MT9 | 30.7 | 0.2767 |

| 60,63,65,70,71,75 | 142 | 107 | ||||||||||||

| 80 | 172 | 132 | ||||||||||||

| LMS10 | MLS9 | 2800 | 5600 | 2500 | 60*,63,65*,70,71,75 | 142 | 104 | 90 | 268 | 230 | 305 | MT10 | 44.55 | 0.5262 |

| 80,85,90,95 | 172 | 132 | ||||||||||||

| 100 | 212 | 167 | ||||||||||||

| LMS11 | MLS10 | 4500 | 9000 | 2200 | 70*,71*,75, | 142 | 107 | 100 | 308 | 260 | 350 | MT11 | 70.72 | 1.1362 |

| 80*,85*,90,95 | 172 | 132 | ||||||||||||

| 100,110,120 | 212 | 167 | ||||||||||||

| LMS12 | MLS11 | 6300 | 12500 | 1900 | 80*,85*,90*,95* | 172 | 132 | 115 | 345 | 300 | 400 | MT12 | 99.54 | 1.9998 |

| 100,110,120,125 | 212 | 167 | ||||||||||||

| 130 | 252 | 202 | ||||||||||||

| LMS13 | MLS12 | 11200 | 20000 | 1600 | * 90, 95 * | 172 | 132 | 125 | 373 | 360 | 460 | MT13 | 137.53 | 3.6719 |

| 100*,110*,120*,125* | 212 | 167 | ||||||||||||

| 130,150,160 | 252 | 202 | ||||||||||||

| LMS14 | MLS13 | 12500 | 25000 | 1500 | 100*,110*,120*,125* | 212 | 167 | 135 | 383 | 400 | 500 | MT14 | 165.25 | 5.1581 |

| 130*,140,150 | 252 | 202 | ||||||||||||

| 160 | 302 | 242 | ||||||||||||

|

Note: 1. The approximate value of mass and moment of inertia is calculated according to the minimum shaft hole recommended by L. 2. The shaft hole diameter with * can be used for Z-type and J-type shaft holes. 3. A and b are the hardness codes of the two materials. 4. L0 is the total length of the coupling when the length of the shaft holes at both ends is L recommended. 5. Type Y is a long cylindrical shaft hole. Type J1 is a short cylindrical shaft hole without counterbore. Type J is a short cylindrical shaft hole with a counterbore, and Type Z is a conical shaft hole with a counterbore. |

||||||||||||||

You may be right | LMZ-Ⅱ Plum Blossom Elastic Coupling | LMS type plum blossom elastic coupling | Interested in other products

- LM type basic plum blossom elastic coupling LT type (formerly TL type) elastic sleeve pin coupling LMD (formerly MLZ) type single flange plum-shaped bullet XL type star elastic coupling T type plum blossom hexagonal water pump counter wheel pad

-

Popular products

- LMS (formerly MLS) type double flange plum-shaped bullet LMZ-Ⅱ (formerly MLL-Ⅱ) integral belt LM type basic plum blossom elastic coupling LMZ-I split brake wheel type plum blossom LMD (formerly MLZ) type single flange plum-shaped bullet

-

Related Products

-

related news